Precision is that fast!

Precision is our business

Whether prototyping or series manufacturing: Benefit from experienced expertise in the fields of development, production and assembly, all under one roof.

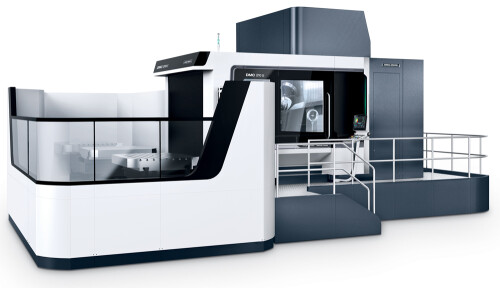

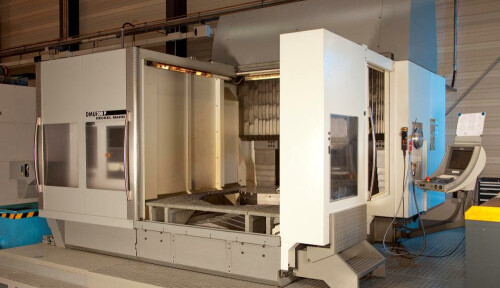

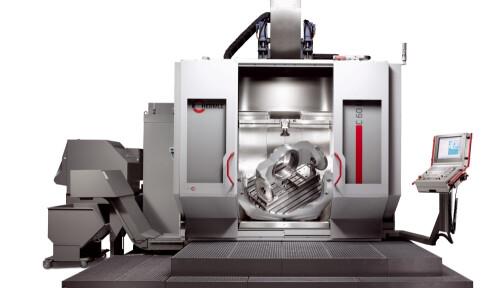

Our machinery and know-how make short processing times possible, even for the most demanding, highest precision machined parts. The 5-axis simultaneous mill and mill-turn machining centres with automatic loading in temperature-controlled production workshops ensure this.

All materials can be processed as semi-finished, cast or welded parts: including steel, aluminium, copper, nickel and titanium alloys as well as plastics.

Perfection is our standard

Modern systems such as Catia V5, Edgecam and VERICUT map the process chain in a closed manner. In this way, we optimize the cost-effectiveness of your added value. Precise documentation and transparent initial sample test reports give you the security of receiving 100% quality from our company at all times.

Products

Production of engine components:

Prototypes and small series

Cylinder heads

Gearbox housing

General engine components

Drive shafts

Fertigung von Fahrwerkskomponenten:

Chassis

Wheel mounts

Subframes

Production of components for concept cars:

Interior components

Chassis components

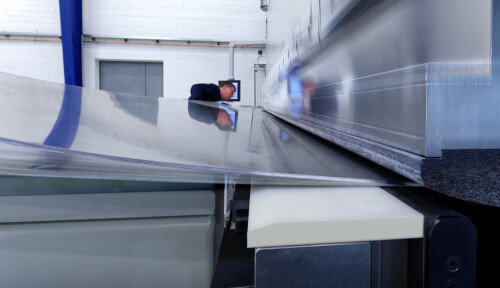

Turning and milling of aerostructures:

Series production and prototypes

Milled ribs

Spars

Mechanical components for doors, gates, etc.

Mounts and connecting elements

Sheet metal forming

Further information about our aviation services is available in our “Aerospace” section.

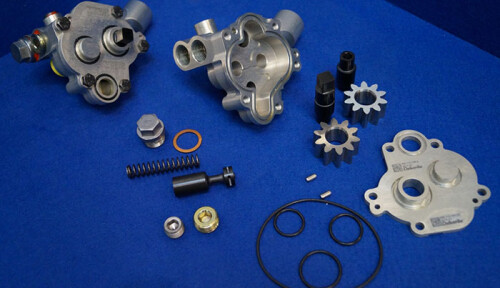

Manufacture of components for installation in spacecraft:

Structural components

Mounting components

Fuel system components

Complete assembly of modules from produced mechanical components

Complete assembly of modules from produced mechanical components, e.g., pumps, carburettors, etc.

Completion of production components, e.g., with bushes, threaded inserts, etc.

We supply our customers with machine components for all industrial areas:

Conveyor technology

Container construction

Welded components

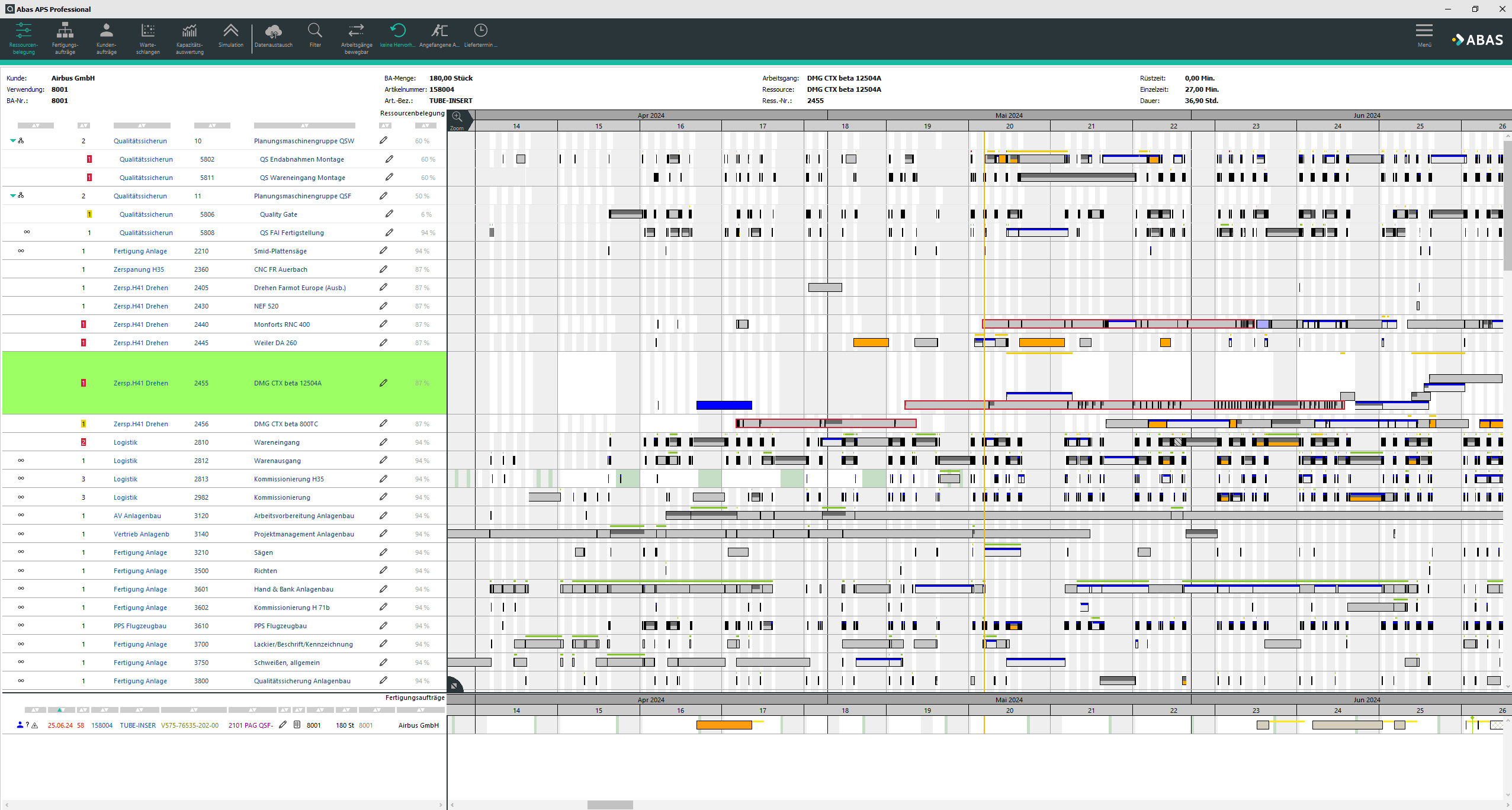

Resources

We annually supply our customers with hundreds of thousands of ready-to-install components produced by Deharde.

Continuous monitoring of individual production orders

Production status can be queried at any time

Cost and schedule monitoring

Dynamic capacity management

Company-wide access through the ERP system

We have extensive production capabilities:

Over 50 machining centres for mechanical production

Flexible production in a three-shift system

More than 120 qualified employees in machining

Approximately 150,000 hours of production annually

3,700 m² of modern production areas

Competent partner network in all production areas relevant to machining

Our internal 5-axis milling equipment consists of:

DMC 340 U - Working area: 2.800 x 3.400 x 1.600 mm with pallet-changing system

DMC 210 U - Working area: 2.100 x 2.100 x 1.250 mm

DMU 340 Gantry - Working Area: 3.400 x 2.800 x 1.250 mm

DMU 200 P - Working area: 1.800 x 2.000 x 1.200 mm

2x Hermle C60 - Working area: 1.200 x 1.300 x 900 mm with air-conditioned interior

Hermle C40 U - Working area: 850 x 700 x 500 mm

2x Grob G 550 - Working area: 800 x 980 x 1020 mm

Hermle C42 U - Working area: 800 x 800 x 550 mm

DMU 70 Evolution - Working area: 750 x 600 x 500 mm

2x Hermle C22 U - Working area: 600 x 450 x 330 mm

DMV 115 - Working area: 1150 x 700 x 550 mm

DMU 60 eVo - 600 x 500 x 500 mm

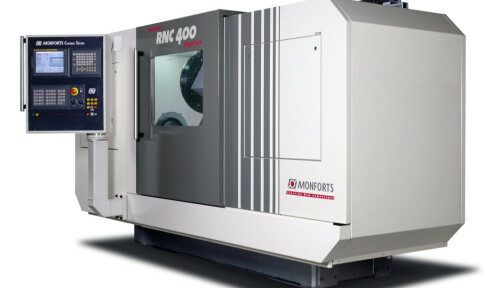

Our internal turning equipment consists of:

Weiler DA260AC

Working area: Ø 560 x 2.000 mmCTX beta 1250 A4

Working area: Ø 340 x 1.200 mmCTX beta 800 TC

Working area: Ø 500 x 750 mmCNC Monforts RNC 400

Working area: Ø 420 x 620 mmGildemeister NEF PLUS 520

Working area: Ø 300 x 620 mmFamot Europe

Working area: Ø 200 x 1.000 mm

Weiler DA260AC

CTX beta 1250 A4

CTX beta 800 TC

CNC Monforts RNC 400

Gildemeister NEF PLUS 520

Our internal grinding equipment consists of:

Elb flat grinding machine

Working area: 2.000 x 600 x 500 mm with 3 axisElb flat grinding machine

Working area: 600 x 400 x 350 mm with 3 axis

Our Fully hydraulic Press Brake for Deharde Polygon Forming™ is putting sheet metal forming to another dimension:

FullyhydraulicPress Brake Deharde Polygon Forming™

Length: 5.500 mm

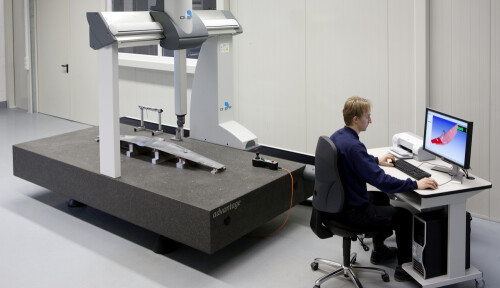

Our staff lives and breathes precision. All our staff is trained to deal with highly precise components and meticulously monitored measuring equipment. The reliable monitoring of our processes is an inviolable standard of both workshop and quality management.

Our internal metrology equipment consists of:

2 x Hexagon Dea Global Advantage

Dimensions: 1.200 x 2.200 x 1.000 mmHexagon Dea Global Advantage

Dimensions: 2.000 x 4.000 x 1.500 mmHexagon ROMER Absolute Arm

Dimensions: 2.000 mmHexagon Romer Scanning Arm 7525 SI

Dimensions: 2.500 mmLasertracker Leica AT 403

Dimensions (volume): 160 m (320 m)Lastertracker API Radion

Dimensions (volume): 50 m (100 m)Lasertracker API Omnitrac 2

Dimensions (volume): 50 m (100 m)

Hexagon Dea Global Advantage

Lasertracker Leica

Lasertracker Leica

Hexagon ROMER Absolute Arm 7520

Management