Best equipment, highest productivity!

We contribute to your success

Our clear goal: to increase the productivity of your company in a reliable and efficient way!

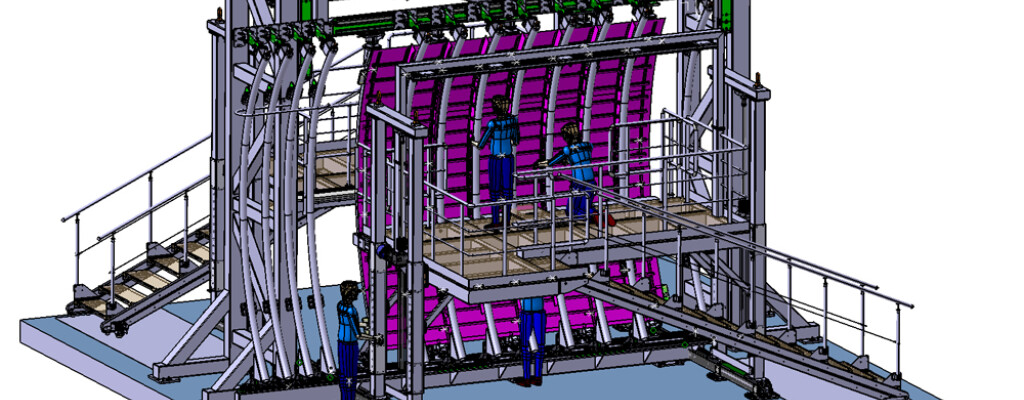

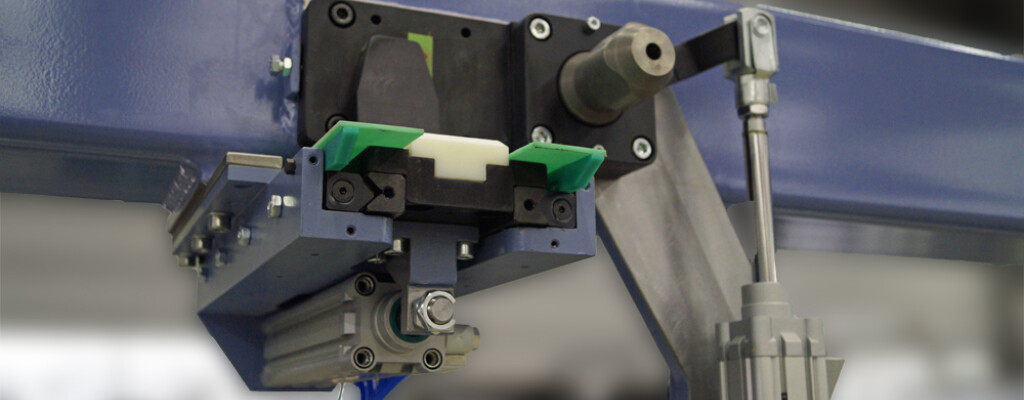

This is what our team of dedicated project managers, creative engineers and experienced technicians stand for. We develop, manufacture and assemble production equipment such as assembly jigs, access solutions, transport devices as well as assembly and equipping stations.

From the quotation up to the integration into your facilities, we retain end-to-end control of your projects. For this reason, we can promise on-time delivery and uncompromising quality at any time.

All-inclusive solutions

Since we combine several manufacturing areas - including Precision Parts and Aerospace - under one roof, our team has interdisciplinary know-how to consolidate in house. This advantage enables us to understand customer requirements from their point of view and fulfill them in an optimal way. We individually develop the most feasible solution for you.

From project planning to commissioning, our dedicated contact persons support you to make our common project a success. Most of our customers come from aerospace industry, but some are also from other sectors such as wind energy or automotive industry.

Products

Resources

Management

Arne Lübben

Head of Jigs and Tools